Our product range is extensive as you will see in this website and our services include a wide variety of cathodic protection engineering and installation offerings.

Cathodic protection cable specifications.

1 2 quality assurance.

Section includes requirements for nstallation of corrosion control i system for pipelines.

Established in 1956 farwest corrosion control company is a world class leader in cathodic protection and corrosion control related products solutions and services.

This specification describes a single conductor pipeline cathodic protection cable.

The quality of the cable is instrumental to any cathodic protection system.

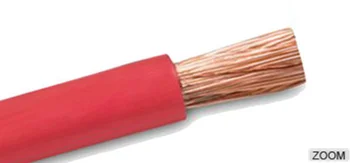

Matcor cathodic protection cable is available in many configurations.

Follow applicable standards for corrosion control.

Performance wire and cable is a trusted supplier of cathodic protection cables for the most demanding direct burial applications.

Part 1 general.

01 july 2012 iso 19011 guidelines for quality and or environmental management systems auditing 4.

Custom put ups are available.

Specification for cathodic protection specifications page 5 of 52 rev.

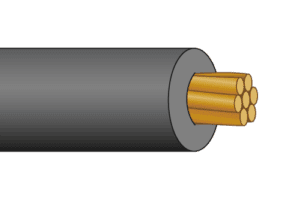

Description cathodic protection cable cp cable or cpc is usually a stranded conductor insulated with hmwpe.

Cathodic protection experience to visit the job site during installation of the impressed current cathodic protection system.

Ratings of 600 volts 75 c application.

For added protection against corrosive gases and brackish water a halar ectfe or kynar pvdf insulation covered by an hmwpe jacket can be used.

We can also customize cp cable orders to meet your specifications with our array of different sizes colors lengths and labeling.

Cathodic protection cable must be highly corrosion resistant and capable of withstanding the rigors of the environments to which they are exposed.

A direct earth burial dc feeder cable for use in cathodic protection systems for pipelines storage tanks water towers bridges railroad tracks pilings well casings cables marine crane structures and other buried or water submerged metallic structures.

Cathodic protection requires the anode to be separate from the metal surface to be protected with an ionic connection through the electrolyte and an electron connection through a connecting cable bolt or similar.

The cathodic protection specialist shall be responsible to the contractor to ensure compliance with these specifications and for observation and testing services specified herein.